The Role of Digitalization in Improving Asset Management for Electrical Equipment

gold bet, tiger exch login, betbook250: Digitalization has become an integral part of almost every industry, revolutionizing the way businesses operate and manage their assets. In the realm of electrical equipment management, digitalization plays a crucial role in improving efficiency, reducing downtime, and maximizing the lifespan of assets. By leveraging digital technologies such as IoT, AI, and data analytics, companies can gain valuable insights into the performance of their equipment, enabling proactive maintenance strategies and cost-effective decision-making.

Understanding the importance of digitalization in asset management for electrical equipment is essential for businesses looking to stay competitive and enhance their operations. In this article, we will explore the key role of digitalization in improving asset management for electrical equipment and how companies can leverage technology to drive business success.

The Impact of Digitalization on Asset Management

Digitalization has transformed asset management practices for electrical equipment by providing real-time data monitoring, predictive analytics, and remote diagnostics capabilities. This allows businesses to monitor the performance of their assets, identify potential issues before they escalate, and take proactive measures to prevent downtime and reduce maintenance costs.

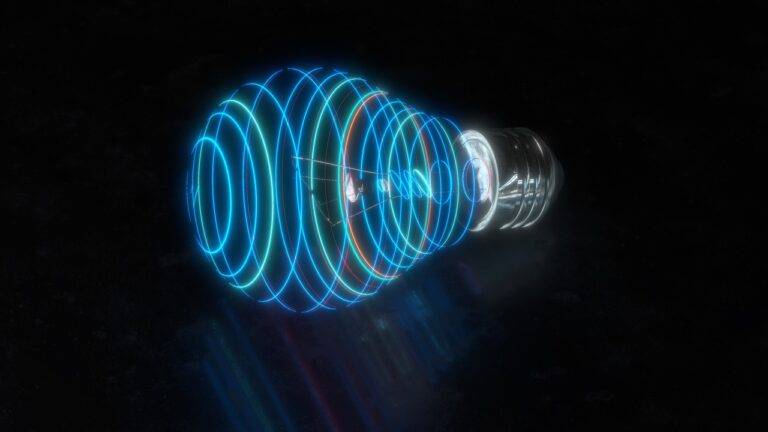

The use of IoT sensors in electrical equipment enables companies to collect critical data points such as temperature, voltage, and current levels in real-time. This data is then transmitted to a centralized system where AI algorithms analyze the information and provide insights into the health and performance of the equipment. By leveraging predictive analytics, businesses can predict potential failures and schedule maintenance activities accordingly, reducing the risk of unexpected breakdowns and optimizing asset performance.

Remote diagnostics tools further enhance asset management for electrical equipment by allowing technicians to monitor and troubleshoot equipment issues from a central location. This not only reduces the need for on-site visits but also enables companies to address problems quickly and efficiently, minimizing downtime and improving overall operational efficiency.

The Role of Data Analytics in Asset Management

Data analytics is a powerful tool that enables businesses to make informed decisions based on the insights generated from vast amounts of data. In asset management for electrical equipment, data analytics plays a crucial role in identifying patterns, trends, and anomalies in equipment performance, helping companies optimize maintenance schedules and improve asset reliability.

By analyzing historical maintenance data, businesses can identify recurring issues, predict potential failures, and implement preventive maintenance strategies to mitigate risks. This proactive approach not only extends the lifespan of electrical equipment but also reduces maintenance costs and enhances operational efficiency.

Data analytics also enables businesses to track key performance indicators (KPIs) such as equipment uptime, downtime, and overall equipment effectiveness (OEE). By monitoring these metrics in real-time, companies can evaluate the performance of their assets, identify areas for improvement, and optimize maintenance processes to maximize asset utilization and productivity.

The Benefits of Digitalization in Asset Management

The adoption of digitalization in asset management for electrical equipment offers a wide range of benefits for businesses, including:

1. Improved Equipment Performance: By monitoring equipment performance in real-time and leveraging predictive analytics, businesses can optimize asset performance, minimize downtime, and enhance reliability.

2. Cost Savings: Digitalization enables companies to implement preventive maintenance strategies, reduce unnecessary maintenance costs, and extend the lifespan of electrical equipment, leading to overall cost savings.

3. Enhanced Operational Efficiency: Remote diagnostics tools and data analytics capabilities streamline maintenance processes, minimize downtime, and improve operational efficiency, enabling businesses to maximize asset utilization and productivity.

4. Better Decision-Making: By leveraging real-time data insights and analytics, businesses can make informed decisions regarding maintenance schedules, asset investments, and resource allocation, leading to better business outcomes.

5. Regulatory Compliance: Digitalization facilitates compliance with regulatory requirements by ensuring that equipment is maintained and monitored according to industry standards, reducing the risk of non-compliance penalties.

6. Scalability: Digital asset management solutions are scalable and flexible, allowing businesses to adapt to changing operational requirements, expand their asset portfolio, and accommodate future growth.

FAQs

1. How can businesses get started with digitalization in asset management for electrical equipment?

Businesses can start by conducting a comprehensive assessment of their current asset management practices, identifying areas for improvement, and evaluating digital solutions that align with their operational needs and goals.

2. What are the key challenges associated with digitalization in asset management?

Some key challenges include data security concerns, integration issues with existing systems, and the need for specialized skills and expertise to implement and maintain digital asset management solutions.

3. How can digitalization improve equipment reliability and performance?

By monitoring equipment performance in real-time, analyzing data trends, and implementing preventive maintenance strategies, businesses can enhance equipment reliability, minimize downtime, and optimize asset performance.

4. What are the key technologies that businesses should consider for digital asset management?

Technologies such as IoT sensors, AI algorithms, data analytics tools, and remote diagnostics capabilities are essential for digital asset management and improving equipment performance.

5. How can businesses measure the return on investment (ROI) of digitalization in asset management?

Businesses can measure ROI by tracking key performance indicators, such as maintenance costs, equipment uptime, and overall equipment effectiveness, and evaluating how digitalization initiatives have contributed to cost savings, efficiency improvements, and operational benefits.

6. What are the best practices for implementing digital asset management solutions?

Some best practices include setting clear objectives and goals, involving key stakeholders in the decision-making process, investing in employee training and development, and continuously monitoring and evaluating the performance of digital asset management initiatives.

In conclusion, digitalization plays a critical role in improving asset management for electrical equipment by enabling businesses to monitor equipment performance, analyze data insights, and implement proactive maintenance strategies. By leveraging digital technologies and data analytics capabilities, companies can enhance equipment reliability, reduce downtime, and optimize asset performance, leading to cost savings, operational efficiency, and better decision-making. With the right strategy and tools in place, businesses can unlock the full potential of digitalization in asset management and drive business success in today’s competitive landscape.